DHT11 incubator with I2C LCD (part 1)

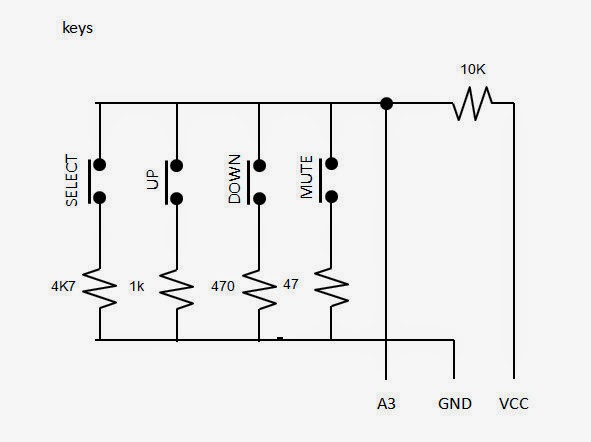

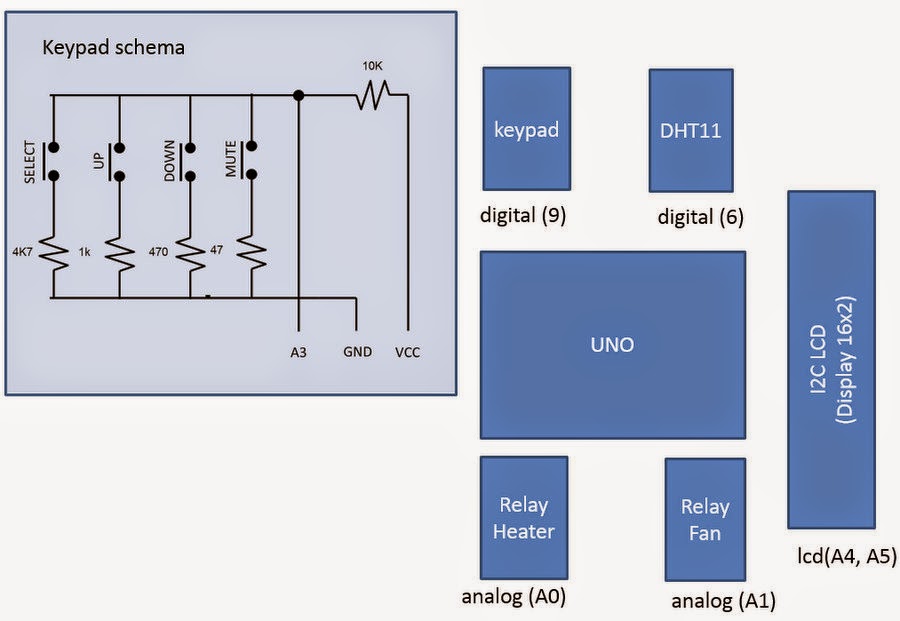

DESCRIPTION DHT11 is applied as a sensor for temperature and humidity. To control temperature, a relay is used and connected to heating elements. Humidity and Temperature are displayed on a 16x2 LCD via I2C/PCF8574. On the next iteration, there will be: an additional relay to control a cooling fan humidity control via pneumatic parts button as controls to set the TempTarget and HumiTarget. However, other incubator implementing LM35 as temperature sensor is already explained on this link EQUIPMENT IN USE This incubator uses a clone of Arduino UNO, DFRduino v2.1, a DHT11 sensor, a relay, and a LCD 16x2 connected to I2C module (PCF8574). DIAGRAM AND PICTURES THE CODE you can grab the code here